Brennan & Co’s Pharmacy Division is leading the charge in providing cutting-edge hospital pharmacy workflow solutions through a partnership with Omnicell and CareFlow Medicines Management. These workflow solutions offer a range of benefits that can help healthcare facilities streamline their medication management processes and reduce errors from point of delivery to hospital to the bedside. By integrating these systems into your work life solutions, you can enjoy automated medication dispensing that minimizes waste, optimizes inventory management, and ensures the right medication is dispensed to the right patient at the right time. These benefits can translate into significant cost savings for healthcare providers and better outcomes for patients. So, if you’re interested in elevating your pharmacy operations to the next level, consider exploring the autonomous pharmacy solutions that Brennan & Co are delivering today.

Hospital Pharmacy Workflow Solutions

Omnicell’s automated pharmacy solutions can work hand in hand with its Careflow Medicines Management software to improve medication management in healthcare organizations. The software provides a centralized platform that integrates with various automated pharmacy solutions to streamline medication dispensing, preparation, and administration. Here are some ways that these solutions work together:

Performance-driven solutions that improve safety, workflow, inventory optimisation, medication management & overall patient care!

XT Automated Medication Dispensing System

Managing medications is a critical part of patient care, you can’t afford to waste time or make mistakes. Omnicell® XT Automated Dispensing Cabinets create a smarter and safer process. They get the right dose of the right medication to the right patient, and also improve the overall patient medication experience and care.

Benefits

-

Improves patient safety – reduces incidences of missed doses or double doses.

- Reduces picking errors thanks to unique guiding light technology.

- Automating the controlled drugs process with an electronic CD register, making it more secure.

- Closing the loop through EPMA integration – so what is prescribed is what is administered.

- Reduces nursing time spent looking for drug cupboard keys or stock which can be returned back to patient care.

Med X

Omnicell’s NEW solution, MedX manages medication and controlled drugs stock and provides one clear view of pharmacy inventory, in real-time, across a hospital, trusts or an integrated care system. At a touch of a button you will be provided with complete traceability and control of all medication inventory.

Benefits

- Reduce unforeseen stock-outs of medication to help ensure that medication is available when and where you need it for your patients.

- Significantly eliminates nursing time spent on searching, managing and ordering medication inventory.

- Reporting suite containing more than 120 reports that can be filtered, viewed, exported and shared with minimal effort and maximum efficiency

- The web based, real time stock level information dashboard and reporting suite links to your hospital reporting system.

Medimat Robotic Medication Pack Dispensing System

Omnicell’s Medimat is a next-generation pack picking robot that automates the storage, management, and dispensing of medication packs for retail and hospital pharmacies. It features a semi-automated filling system that optimizes space usage and allows for quick and simple inventory replenishment. The Medimat’s unique Fill-in-Door feature allows staff to place items anywhere on the shelf without manual scanning.

Benefits

- Increased efficiency – Automates medication storage, management, and dispensing, reducing manual labor and increasing efficiency.

- Improved accuracy – Medimat’s automated processes reduce the risk of human error, ensuring the right medication is dispensed to the right patient.

- Space optimization – Medimat’s chaotic filling system optimizes space usage, allowing for more medications to be stored in a smaller footprint.

- Cost-effective – Medimat can reduce labor costs and inventory management by automating processes and increasing efficiency.

- Customizable – Medimat is a modular system that can be customized to meet pharmacy needs, maximizing productivity.

Omnicell VBM 200F

The Omnicell® VBM 200F is the only small footprint, automated pharmacy blister card packaging machine that efficiently and accurately fills and checks SureMed® by Omnicell multiple medication blister cards, creating a seamless active workflow. The VBM 200F ensures pharmacies have the competitive advantage to easily scale their business. This leads to immediate improvements to medication adherence and patient outcomes.

Benefits

- Help utilise staff for value added services to improve patient care – Omnicell VBM enables you to free up staff time to focus on patient care and other initiatives.

- Easily scale your pharmacy – Take on more community patients and care homes, without the need to increase your headcount.

- Benefits for your patients – A full colour printing with medication images and dosage instructions are included in the MDS pack. Patients feel informed about the medications that they are taking.

- Integration – Integrates with Omnicell’s eMAR solution – our award winning eMAR solution for care homes. This automates the entire medication management and administration process. Both pharmacies and care homes can have complete traceability from the moment medications are dispensed, to the point when they’re being administered.

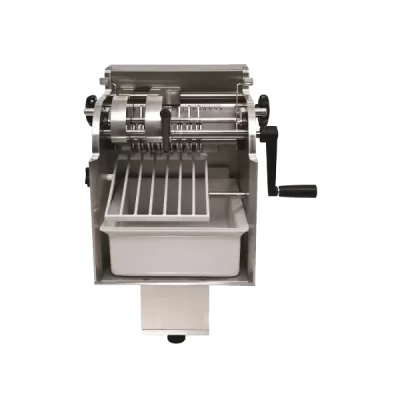

Omnicell DB500 Deblistering machine

Take the strain and pain out of removing tablets from their packaging with our range of de-blistering machines, designed specifically to transform the time-consuming task of de-blistering. These compact desktop machines not only reduce the risk of repetitive injuries and forefingers from de-blistering by hand, it is quick to set-up for different medication packs with no tools needed.

Benefits

- Quickly deblister medication – The DB500 can de blister up to 280 capsules or tablets per minute

- Easy to use – So straightforward to use that operators can be trained in a matter of minutes.

- Flexible to meet your needs – Works with vast majority of medication packs used in today’s pharmacy

Electric Pill Grinder

The Severo Electric Pill Grinder is a reliable and efficient device that can be used to grind pills quickly and accurately. It has a patented grinding mechanism that ensures that pills are ground to a fine powder without any loss of medication. It is also easy to use and can be operated with one hand, making it ideal for patients with limited mobility or dexterity. Additionally, it can grind a wide range of pills, making it an ideal tool for healthcare facilities that need to grind medication for patients with varying needs.

Benefits

-

Time-saving –

Quickly grind medication without having to spend time manually crushing pills with mortar and pestle, thus saving time and increasing efficiency.

- Precise and consistent – The grinder is designed to provide a consistent and fine powder, which ensures that patients receive the correct dosage every time.

- Easy to use – Easy to use and does not require any special training

Tablet Counter

The Kirby Lester KL1 tablet counter can be used to count and dispense medication quickly and accurately. It is equipped with advanced counting technology that ensures the correct amount of medication is dispensed every time. Its speed is up to 20 tablets per second, allowing pharmacy staff to focus on other important tasks. It is also versatile and can handle a wide range of medication sizes and shapes. It can also be programmed to count medication for clinical trials and research studies, making it a valuable tool for pharmaceutical companies and research organizations.

Benefits

-

Accuracy –

Uses advanced technology to ensure that medication is counted and dispensed accurately. This helps to reduce medication errors and improve patient safety.

- Speed – Can count and dispense medication at a much faster rate than manual counting, which helps to save time and increase efficiency in the pharmacy.

- Versatility – The KL1 tablet counter can handle a wide range of medication sizes and shapes, including tablets, capsules, and pills.

KL1 Tablet Counter Brochure

Tablet Counter

The Kirby Lester KL1 tablet counter can be used to count and dispense medication quickly and accurately. It is equipped with advanced counting technology that ensures the correct amount of medication is dispensed every time. Its speed is up to 20 tablets per second, allowing pharmacy staff to focus on other important tasks. It is also versatile and can handle a wide range of medication sizes and shapes. It can also be programmed to count medication for clinical trials and research studies, making it a valuable tool for pharmaceutical companies and research organizations.

Benifits

-

Accuracy –

Uses advanced technology to ensure that medication is counted and dispensed accurately. This helps to reduce medication errors and improve patient safety.

- Speed – Can count and dispense medication at a much faster rate than manual counting, which helps to save time and increase efficiency in the pharmacy.

- Versatility – The KL1 tablet counter can handle a wide range of medication sizes and shapes, including tablets, capsules, and pills.

KL1 Tablet Counter Brochure

Check Out eezycd® Controlled Drug Liquid Accuracy Measures

Controlled Drug Liquid Accuracy Measures Video Overview

eezycd® Controlled Drug Accuracy Measures

The Controlled Drug Accuracy Measures are built to save time during mandatory stock checks. They enable staff to be with their patients instead of being left in the treatment room trying to resolve discrepancies. Currently, stock checks are performed by either looking at the solution and approximating the fill volume, or physically measuring the liquid into another vessel. Physical measuring causes residual waste, possible spillages, and environmental contamination. Approximating is obvious, but an incorrect eye for the volume stores up troubles and investigations for later.

Benefits

Staff can now take accountability without having to open a bottle of controlled drugs, reducing stress and time lost to practice.

Daily stock checks take time, cause loss of liquid and take staff away from where they need to be.

The Controlled Drug Accuracy Measures will improve compliance, accuracy, and reduce the need for intervention, investigation, and documentation.